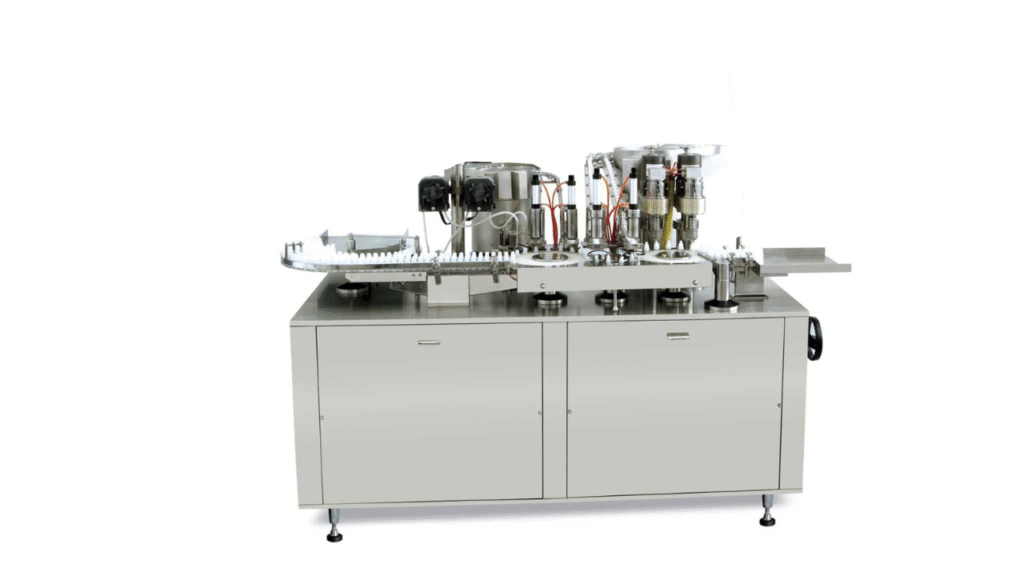

Eye Drop Filling and Capping Machine:

Precise filling with anti-drip nozzles

Compact design for cleanroom use

Integrated sealing and capping functions

GMP-compliant stainless steel build

Easy to clean, operate, and maintain

Ideal for ophthalmic, nasal, and ear drop production

Technical Specifications

| Parameter | Specification |

|---|---|

| Filling Range | 2ml – 30ml (customizable) |

| Filling Accuracy | ±1% |

| Filling Speed | Up to 60 bottles/min |

| Bottle Diameter | 10mm – 30mm |

| Power Supply | 220V / 50Hz, single phase |

| Machine Material | SS304 / SS316 contact parts |

| Control System | PLC with touch screen (optional) |

| Air Pressure Requirement | 0.6 – 0.8 MPa |

| Operation Mode | Fully automatic / Semi-automatic (options) |

| Dimensions | Customizable as per requirement |