OUR PRODUCTS

Aerosol Filling Machine by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Filling Capacity (cans/min) | 35-50 cans/min |

| Liquid Filling Volume (ml) | Max 550ml/one stroke/head |

| Gas Filling Accuracy | ±0.03 Mpa |

| Liquid Filling Accuracy | ≤1% |

| Applicable Can Diameter (mm) | 40-65 (customizable) |

| Applicable Can Height (mm) | 70-300 (customizable) |

| Applicable Valve (mm) | 25.4 mm (1 inch) male & female BOV |

| Propellant | N2, Compressed Air |

| Max Gas Consumption | 6m³/min |

| Power | AC 220/380V, 50HZ |

| Air Source | 0.6-0.7 Mpa |

Double Cone Blender by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | DCB-50 to DCB-1000 (various capacities) |

| Working Capacity | 50 – 1000 Liters (customizable) |

| Total Capacity | Up to 2000 Liters |

| Material | SS304 / SS316L |

| Blending Time | 10 – 30 Minutes (depending on material) |

| Speed | 10 – 20 RPM |

| Drive Motor | 1 – 10 HP (as per model) |

| Discharge Valve | Butterfly / Ball Valve |

| Power Supply | AC 220/380V, 50Hz, 3 Phase |

| Surface Finish | Mirror / Matt Finish |

| Safety Features | Overload protection, Emergency stop |

Bottle Washing Machine by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | Automatic / Semi-Automatic |

| Output Capacity | 40 – 200 bottles/min (based on model) |

| Bottle Diameter | 30 – 100 mm |

| Bottle Height | 50 – 300 mm |

| Washing Stations | 4 to 8 stages (customizable) |

| Washing Media | Air, Water, Detergent, Filtered Water |

| Pump Capacity | 0.5 – 2 HP (SS centrifugal pump) |

| Construction Material | SS304 / SS316L |

| Power Supply | AC 220/380V, 50Hz, 3 Phase |

| Control System | PLC / Manual |

| Air Consumption | 2 – 4 CFM @ 6 Bar |

Sterilization Tunnel by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | GMP Compliant – ST Series |

| Output Capacity | 50 – 300 bottles/min (varies by model) |

| Heating Zone Temperature | Up to 320°C (adjustable) |

| Cooling Zone Temperature | Room Temperature to 50°C |

| Number of Zones | Pre-heating, Sterilizing, Cooling |

| Air Filtration | HEPA Filter Class H13/H14 |

| Air Flow | Laminar Flow (100 Class Clean Air) |

| Construction Material | SS316L (product contact) / SS304 |

| Control System | PLC with HMI Touchscreen |

| Power Supply | AC 380V, 50Hz, 3 Phase |

| Safety Features | Overheat Protection, Emergency Stop, Alarm System |

Water Distilled Plant by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Multi-Column Water Distillation Plant |

| Capacity Range | 10 to 5000 liters/hour (customizable) |

| Type | Multi-Effect / Single Effect Distillation |

| Material of Construction | SS316L (contact parts), SS304 (non-contact parts) |

| Water Source | Purified Water / RO Water |

| Distillate Quality | Meets IP / BP / USP standards for WFI |

| Conductivity | < 1 µS/cm |

| Output Temperature | 90°C – 95°C (standard), optional cooling available |

| Heating Source | Industrial Steam / Electrical Heaters |

| Control Panel | PLC-based with HMI / Manual Control (optional) |

| Automation | Semi / Fully Automatic |

| Applications | Pharmaceuticals, Biotech, Laboratories, Hospitals |

| Compliance | GMP, cGMP, USFDA, CE Certified |

Perforated Table by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Material of Construction | Stainless Steel 304 / 316 (optional) |

| Tabletop Type | Perforated SS Sheet with Smooth Edges |

| Table Dimensions (L x W x H) | 1200 x 600 x 850 mm (customizable) |

| Perforation Size | 3 – 6 mm diameter holes |

| Load Capacity | 100 – 200 kg (uniformly distributed) |

| Leg Design | SS Tubular Frame with Adjustable Nylon/PU Legs |

| Finish | Matt / Mirror Finish (as per requirement) |

| Application | Pharmaceutical, Food, Cleanroom & Industrial Use |

| Optional Add-ons | Back Splash, Side Guard, Caster Wheels |

| Compliance | GMP & FDA Standards |

Fluid Bed Dryer by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | FBD-5 to FBD-500 (various capacities) |

| Batch Size | 5 kg to 500 kg (dry powder) |

| Inlet Air Temperature | Ambient to 120°C (adjustable) |

| Drying Time | 20 – 60 minutes (depending on product) |

| Heating Mode | Electric / Steam / Hot Water |

| Blower Motor | 2 HP to 30 HP (as per model) |

| Material of Construction | SS316L (product contact), SS304 (non-contact) |

| Control System | PLC with HMI / Manual Panel |

| Filter Type | Antistatic & Washable Filter Bags |

| Safety Features | Explosion vent, Overheat protection, Emergency stop |

| Compliance | GMP, CE, cGMP Standards |

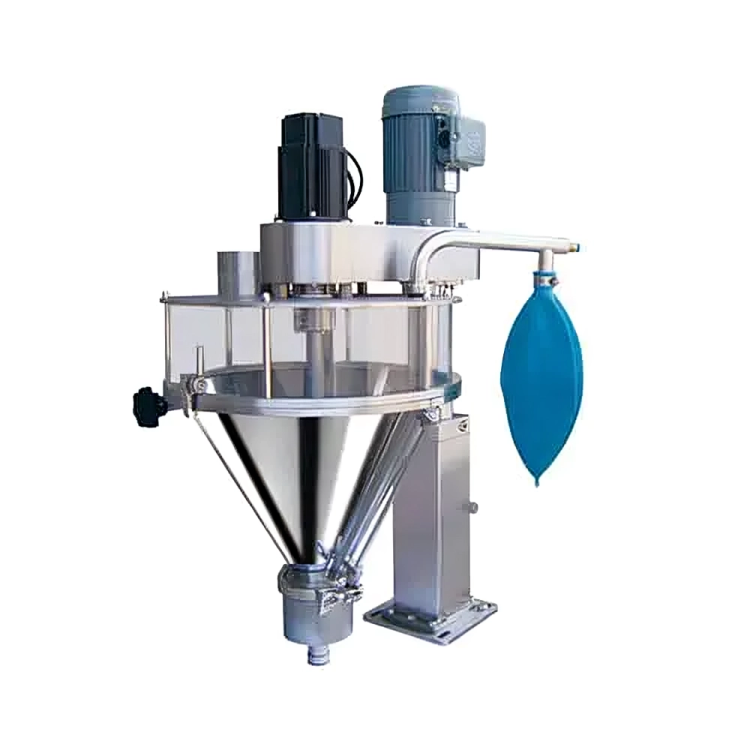

Auger Filling Machine by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | Automatic / Semi-Automatic Auger Filler |

| Filling Range | 10 gm to 5000 gm (depending on auger and container) |

| Filling Accuracy | ±1% (depending on product) |

| Output Capacity | 20 – 60 fills/min (based on product flow and model) |

| Hopper Capacity | 25 – 50 Liters (customizable) |

| Material of Construction | SS304 / SS316L (contact parts) |

| Container Type | Bottles, Jars, Pouches, Cans, etc. |

| Drive Mechanism | Servo / Clutch Brake System |

| Control System | PLC with Touchscreen HMI |

| Power Supply | AC 220V/380V, 50Hz |

| Applications | Powdered products like spices, flour, milk powder, chemicals, pharma powders |

Homogenizer Pump by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | Single / Two-Stage Homogenizer Pump |

| Capacity | 100 – 20,000 LPH (customizable) |

| Pressure Range | 100 – 1500 bar |

| Stages | Single Stage / Double Stage |

| Material of Construction | SS316L (contact parts), SS304 (non-contact) |

| Valve Type | Ball / Disk / Mushroom Type |

| Plunger Material | Special alloy with hard coating |

| Sealing | Hydraulic or Mechanical Seals |

| Motor Power | 5 HP to 75 HP (as per model) |

| Control System | Manual / PLC with HMI |

| Applications | Dairy, Beverages, Pharmaceuticals, Cosmetics, Emulsions |

Lab Cabinets by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Wall-Mounted / Floor Standing Lab Cabinets |

| Material of Construction | Powder-Coated MS, SS304, or SS316 (customizable) |

| Cabinet Dimensions | 900 x 450 x 1800 mm (custom sizes available) |

| Door Type | Solid / Glass / Sliding / Hinged |

| Number of Shelves | 2 to 5 adjustable shelves |

| Finish | Matt / Mirror / Epoxy Coated / Electro-polished |

| Locking Mechanism | Cam Lock / Latch Lock |

| Load Capacity | Up to 100 kg per shelf |

| Ventilation | Optional vents for chemical storage |

| Usage | Pharmaceutical, Chemical, R&D Labs, Hospitals |

| Compliance | GMP & ISO Standards |

Granulator by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | Rapid Mixer Granulator / Oscillating Granulator |

| Batch Capacity | 5 kg to 500 kg (model dependent) |

| Mixing Time | 6 – 12 minutes per batch |

| Granulation Time | 1 – 4 minutes |

| Impeller Motor | 2 HP to 30 HP |

| Chopper Motor | 1 HP to 7.5 HP |

| Material of Construction | SS316L (contact parts), SS304 (non-contact) |

| Discharge | Pneumatic / Manual Discharge Valve |

| Control System | PLC with HMI / Manual Panel |

| Safety Features | Interlocks, Emergency Stop, Overload Protection |

| Application | Pharmaceuticals, Nutraceuticals, Food, Chemicals |

Coating Pan by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Model | Standard / Perforated Coating Pan |

| Pan Diameter | 12” to 60” (300 mm to 1500 mm) |

| Batch Capacity | 5 kg to 300 kg (as per model) |

| Pan Speed | 2 – 15 RPM (variable) |

| Drive Motor | 0.5 HP to 5 HP |

| Blower Heater Capacity | 1 KW to 10 KW (with temperature control) |

| Material of Construction | SS316 / SS316L (contact parts) |

| Control Panel | SS panel with PID / PLC & HMI (optional) |

| Hot Air Blower | Integrated / External with duct connection |

| Exhaust System | Optional exhaust blower with ducting |

| Application | Tablet coating with sugar, film, or enteric layers |

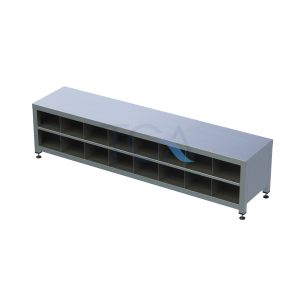

Shoe Locker by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Shoe Locker |

| No. of Compartments | 6 / 9 / 12 / 18 / 24 / 36 (customizable) |

| Material of Construction | SS304 / SS316 (as required) |

| Dimensions | 900 x 450 x 1800 mm (varies by model) |

| Compartment Size | Customized to fit industrial and cleanroom needs |

| Door Type | Individual hinged doors with label holders |

| Finish | Matt / Mirror Polish |

| Ventilation | Perforated design for air circulation |

| Locking System | Hasp & staple / Cam lock / Digital lock (optional) |

| Mounting | Floor Standing or Wall Mounted |

| Applications | Pharmaceuticals, Labs, Cleanrooms, Industrial Zones |

Tea Snack Trolley by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Tea & Snack Service Trolley |

| Material of Construction | Stainless Steel 304 / 316 |

| Overall Dimensions | 900 x 500 x 900 mm (L x W x H) – customizable |

| No. of Shelves | 2 or 3-tier (flat or tray-type) |

| Top Surface | Flat / Raised Edge / Tray-Style with anti-spill guard |

| Handle Type | Ergonomic Push Handles on Both Sides |

| Castors | 4 Swivel Castors (2 with brakes), SS or PU wheels |

| Load Capacity | 100 – 150 kg (evenly distributed) |

| Finish | Matt / Mirror Polish |

| Applications | Pharma Canteens, Hospitals, Labs, Office Service |

Mooping Trolley by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Mopping Trolley (GMP Model) |

| Material of Construction | SS304 / SS316 (as required) |

| Bucket Capacity | 20 – 25 Liters per bucket |

| No. of Buckets | Single / Double / Triple Bucket Options |

| Bucket Colors | Color-coded for segregation (Red, Blue, Yellow, Green) |

| Wringer Type | Heavy-duty SS wringer or plastic wringer (optional) |

| Frame Design | Welded SS tubular structure with ergonomic handle |

| Castor Wheels | 4 Swivel PU Wheels (2 with brakes) |

| Finish | Matt / Electro-polished (for cleanroom use) |

| Applications | Pharmaceutical, Cleanroom, Hospital, Food Industry |

Portable Sink

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Portable Sink Unit |

| Material of Construction | SS304 / SS316 (as required) |

| Sink Bowl Size | 400 x 400 x 200 mm (customizable) |

| Overall Dimensions | 900 x 600 x 850 mm (L x W x H) – customizable |

| Water Supply | Manual / Foot Pedal / Sensor-Activated Tap |

| Waste Collection | Integrated SS tank or direct drain outlet |

| Fresh Water Tank | 20 – 50 Liters (depending on model) |

| Mobility | Mounted on 4 swivel castors (2 with brakes) |

| Finish | Matt / Mirror Finish (GMP compliant) |

| Optional Features | Soap Dispenser, Paper Towel Holder, UV Sterilizer |

| Applications | Pharma, Food Units, Outdoor Clinics, Events, Labs |

Step Over Bench

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Step Over Bench |

| Material of Construction | SS304 / SS316 (as per client requirement) |

| Dimensions (L x W x H) | 1200 x 300 x 450 mm (customizable) |

| Top Surface | Flat / Perforated / With Storage Shelf |

| Design | Single Side / Double Side Seating |

| Leg Type | Round / Square Pipe with Anti-Skid Stoppers |

| Load Capacity | Up to 200 kg |

| Surface Finish | Matt / Mirror / Electro-Polished Finish |

| Mounting Type | Freestanding / Floor Fixed (optional) |

| Applications | Cleanrooms, Pharma Change Rooms, Hospitals, Labs |

| Compliance | GMP & ISO Standards |

SS Pallet

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Pallet |

| Material of Construction | SS304 / SS316 (as per application) |

| Dimensions (L x W x H) | 1000 x 1000 x 150 mm (customizable) |

| Load Capacity | 500 – 2000 kg (uniformly distributed) |

| Top Design | Flat / Perforated / Slotted Surface |

| Bottom Support | 3 or 4 Leg / Full Perimeter Frame |

| Surface Finish | Matt / Mirror / Electro-polished |

| Handling Compatibility | Hand Pallet Truck & Forklift Operable |

| Corrosion Resistance | High – suitable for cleanroom & wet areas |

| Applications | Pharmaceutical, Food Industry, Cold Storage, Warehousing |

| Compliance | GMP & FDA Standards |

Three Layer Table by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Three Layer Stainless Steel Utility Table |

| Material of Construction | SS304 / SS316 (as per application) |

| Number of Layers | 3 Tiers (Top + 2 Lower Shelves) |

| Dimensions (L x W x H) | 1200 x 600 x 850 mm (customizable) |

| Load Capacity | 100 – 200 kg (uniformly distributed) |

| Top Surface | Flat / Perforated / Raised Edge (optional) |

| Shelf Clearance | 300 – 350 mm between each layer (adjustable) |

| Legs & Support | SS tubular legs with cross-bracing for stability |

| Mobility | Fixed or with Lockable Castor Wheels (optional) |

| Finish | Matt / Mirror / Electro-Polished |

| Applications | Pharmaceutical, Laboratory, Hospital, Food Industry |

Safety Grill by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Safety Grill |

| Material of Construction | SS304 / SS316 (customized as per application) |

| Bar Size | Ø12 mm / Ø16 mm / Flat or Square Bar (customizable) |

| Frame Type | Welded SS Frame with Anchor Plates |

| Finish | Matt / Mirror / Electro-Polished |

| Mounting Type | Wall Mounted / Floor Mounted / Ceiling Mounted |

| Grill Pattern | Horizontal / Vertical / Mesh Type / Custom Design |

| Dimensions | As per site requirement (custom-built) |

| Application Area | Cleanrooms, Equipment Zones, Air Handling Areas |

| Safety Features | Rounded Edges, Anti-Rust, High Strength Construction |

| Compliance | GMP, ISO, and Facility Safety Norms |

Canteen Table with Stools by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Canteen Dining Table with Fixed Stools |

| Seating Capacity | 4 / 6 / 8 Person (customizable) |

| Material of Construction | SS304 / SS316 Frame with SS / Granite / MDF Top |

| Table Dimensions | 1800 x 600 x 750 mm (8-seater standard) |

| Stool Design | Round / Square Fixed Stools Welded to Frame |

| Structure Type | Single Frame Welded Construction |

| Finish | Matt / Mirror Finish (as per order) |

| Mounting | Floor Mounted or Free Standing |

| Corrosion Resistance | High – suitable for industrial and humid environments |

| Applications | Factory Canteens, Pharma Units, Hospitals, Mess Halls |

SS Stools by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Stool |

| Material of Construction | SS304 / SS316 (as per client requirement) |

| Top Design | Flat / Perforated / Cushion-Top (optional) |

| Height | 450 mm standard (adjustable on request) |

| Frame Type | Round or Square Pipe with Reinforced Bracing |

| Legs | 4 Legs with Nylon / Rubber Stoppers |

| Finish | Matt / Mirror / Electro-Polished |

| Load Capacity | Up to 150 kg |

| Portability | Lightweight and Easy to Move |

| Applications | Pharma, Labs, Hospitals, Food Industry, Cleanrooms |

WFI Loop by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| System Type | WFI (Water for Injection) Distribution Loop |

| Material of Construction | SS316L with < 0.6 µm Ra Electro-polished Finish |

| Piping Standard | ASME BPE / DIN / ISO Certified Tubing |

| Loop Design | Continuous Circulation with Sloped Return |

| Flow Rate | 1 to 20 m³/hr (customized to application) |

| Temperature Range | 80°C – 90°C (hot loop) / ambient (cold loop) |

| Sterilization Method | Online with Pure Steam or Electric Heater |

| Control System | PLC with HMI / SCADA integration |

| Connections | Tri-Clamp / Orbital Welded / Aseptic Design |

| Insulation | PUF / Mineral Wool with SS Cladding |

| Monitoring | Online Temp, Flow, Conductivity, TOC Sensors |

| Compliance | US FDA, EU GMP, USP, EP, ASME BPE |

Aerosol Crimping Machine by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Semi-Automatic Aerosol Crimping Machine |

| Crimping Head | Single Head (Manual Can Placement) |

| Production Capacity | 15 – 25 cans per minute |

| Crimping Diameter | 25.4 mm (1 inch standard valve) |

| Crimping Accuracy | ±0.1 mm |

| Applicable Can Diameter | 35 – 65 mm (customizable) |

| Applicable Can Height | 80 – 300 mm |

| Power Source | Air Operated (no electricity required) |

| Air Pressure | 0.6 – 0.8 Mpa |

| Construction | SS304 Body with Hardened Crimping Tools |

| Applications | Aerosol Products: Cosmetics, Pharma, Paint, Insecticides |

SS Bolts by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Stainless Steel Bolts |

| Material Grade | SS304 / SS316 / SS202 (as required) |

| Thread Type | Full Thread / Half Thread |

| Head Type | Hex Head / Allen Head / Round Head / Customized |

| Available Sizes | M4 to M36 (custom lengths available) |

| Length Range | 10 mm to 300 mm |

| Thread Standard | Metric (DIN/ISO) / UNC / UNF |

| Finish | Polished / Passivated / Electro-Polished |

| Corrosion Resistance | High – suitable for cleanrooms & outdoor use |

| Applications | Pharma, Food Industry, Cleanrooms, Construction, Machinery |

| Packaging | Boxed / Bulk Packed (as per order size) |

Manual Crimping Machine by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Manual Aerosol Crimping Machine |

| Operation Mode | Manual Hand Lever Operated |

| Production Capacity | 8 – 12 cans per minute (operator dependent) |

| Crimping Diameter | 25.4 mm (1 inch standard valve) |

| Crimping Type | Fixed Die / Adjustable (as required) |

| Applicable Can Diameter | 35 – 65 mm (customizable) |

| Applicable Can Height | 80 – 300 mm |

| Construction | MS Powder Coated / SS304 Frame (optional) |

| Weight | 15 – 25 kg |

| Power Requirement | Not required (manual operation) |

| Applications | Small Batch Aerosol Filling – Pharma, Cosmetics, Testing Labs |

Aerosol Filling Machines by GBES

Product Technical Specifications:

| Specification | Details |

|---|---|

| Product Type | Semi-Automatic Aerosol Filling Machine |

| Production Capacity | 15 – 30 cans per minute |

| Filling Stations | 3-in-1: Liquid Filling, Crimping, Gas Filling |

| Filling Volume | 20 – 500 ml (adjustable) |

| Filling Accuracy | ±1% (liquid), ±0.03 Mpa (gas) |

| Crimping Diameter | 25.4 mm (1 inch standard valve) |

| Applicable Can Diameter | 35 – 65 mm (customizable) |

| Applicable Can Height | 80 – 300 mm |

| Propellants Supported | LPG, DME, CO₂, N₂, Compressed Air |

| Air Pressure Required | 0.6 – 0.8 Mpa |

| Construction | SS304 Structure with Alloy Filling Heads |

| Operation | Pneumatic – no electrical components |

| Applications | Pharma, Cosmetics, Insecticides, Paints, Automotive |